Introduction

Coal is a general concept that includes raw coal and its products. Primary coal is a fossil fuel that usually looks like black or brown rock and is composed of carbonized plant materials. Primary coal is divided into three general categories: hard coal (coking and thermal coal), brown coal (semi-bituminous coal and lignite) and peat. The higher the carbon content of coal, the higher its quality and transparency. Different coals can be distinguished from each other by their physical and chemical properties, these properties determine its price and suitability for different users.

- The amount of carbon, ash, volatiles, moisture, sulfur and salts in coal are among the most important properties of coal and are significantly controlled by coal preparation methods.

- Coal preparation involves washing coal, separating the soil from the rock and crushing into graded sized chunks (sorting).

- The more of waste material that can be removed from coal, the lower its total ash content, the greater its market value and the lower its transportation costs.

Uses

The purpose of these preparations has been to economically improve the quality of coal to make it suitable for a specific uses:

The main uses of coal in the world are used as fuel in power generating thermal power plants, in the production of steam by steam turbines, in industrial plants, railways, ships and also as domestic fuel in some countries. Approximately 87% of the world’s coal is burned to generate heat and other related energy. It is obvious that by burning coal, by-products such as combustible gases, coke and tar are also obtained.

Coal is also used in other industries, the most important of which are alumina refining, paper making, chemical and pharmaceutical industries, refined bitumen, ammonia gas recovery for chemical fertilizer production, pigments, graphite for electrodes, water treatment, materials Cosmetics, liquid fuels, energy sources for the production of cement, plastic products and fibers, production of metals, alloys, ferroalloys and … mentioned.

The main application of thermal coal in Iran is in the alloy and ferroalloy industries. This coal should be processed using new coal washing technologies and the percentage of carbon, volatiles, moisture, sulfur and salts in the coal should be controlled.

This coal should be washed using modern coal washing technologies and the percentage of carbon, volatiles, moisture, sulfur and salts in the coal should be controlled.

Sales

Aron Carbon Faravar Company, with using modern coal washing technologies, is able to produce and supply washed and processed thermal-coal in various types of granulation required by the steel, ferroalloy, coke, sponge iron, … industries. The company is proud to offer its washed and granulated coal products to industries in different countries. Our products are of high quality. Having multiple customers from different countries. We’re keen to join them on this journey and continue supplying our products and services.

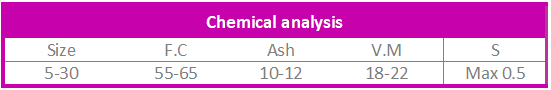

At present, Aron Carbon Faravar Company offers its Cleaned coal product with the following granulation and chemical analysis:

Category

- Cleaned coal 5–30 mm

- Fine Cleaned coal 1–5 mm

- Fine Cleaned coal 0–1 mm

Packing

- In Big bags

- In bulk